Product center

Product Center

During the production process of soft capsules, the gelation process is essential and crucial, with vacuum defoaming being a key step in the gelatin melting of softgel capsules.

Conventional vacuum defoaming in the gelatin melting of soft capsules requires manual control of the air inlet valve, vacuum valve, and vacuum pump of the gelatin meltign tank by the operator, which is time-consuming and laborious. Due to variations in operators' techniques, different results can be obtained when different gelatin melting workers perform vacuum defoaming, leading to variations in the water content of gel batches. Automating the vacuum defoaming process in the gelatin melting of soft capsules can effectively address this issue.

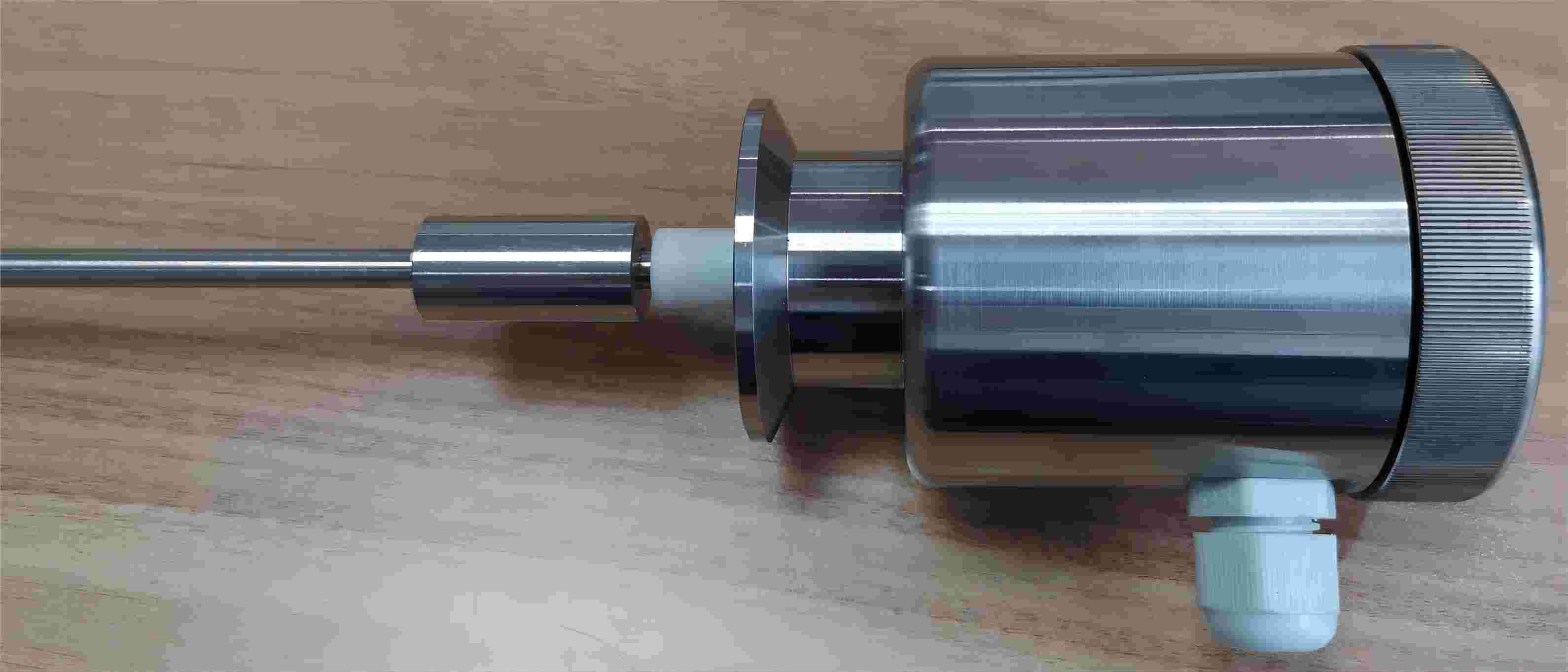

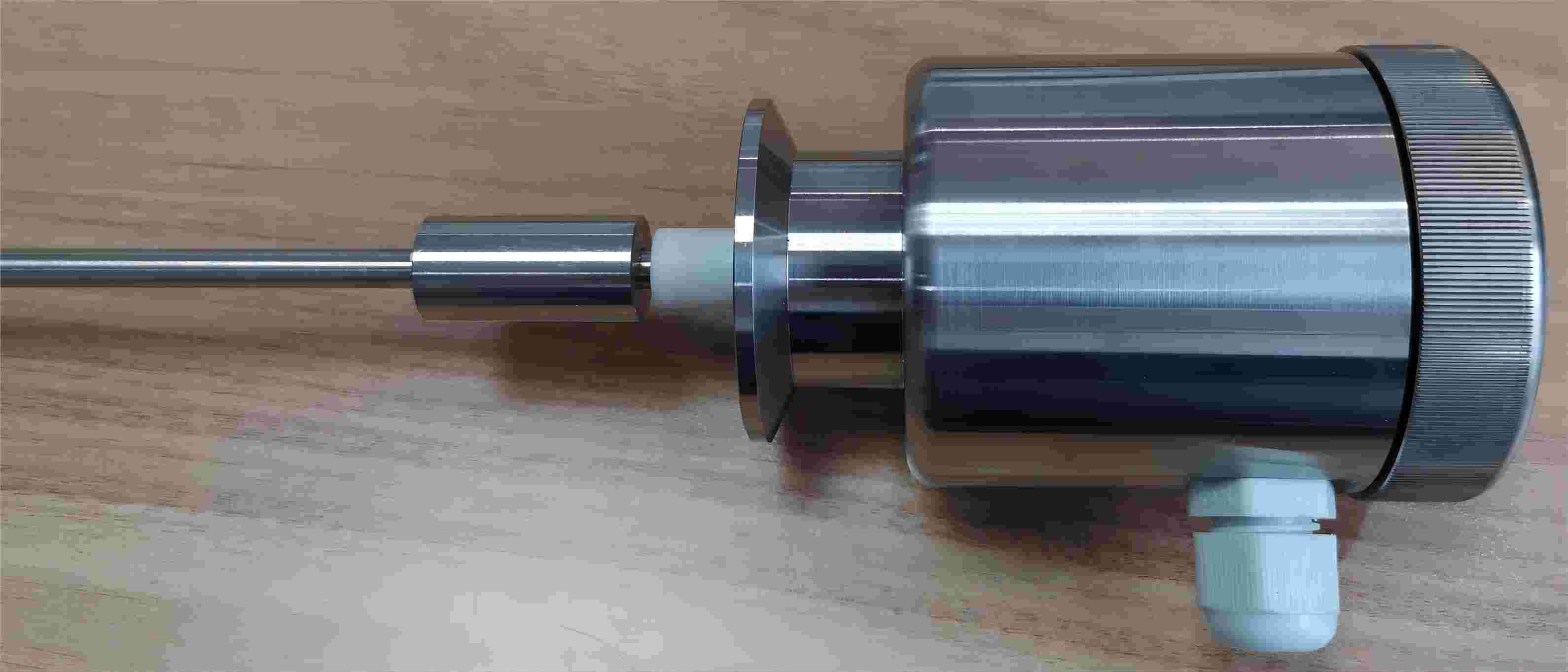

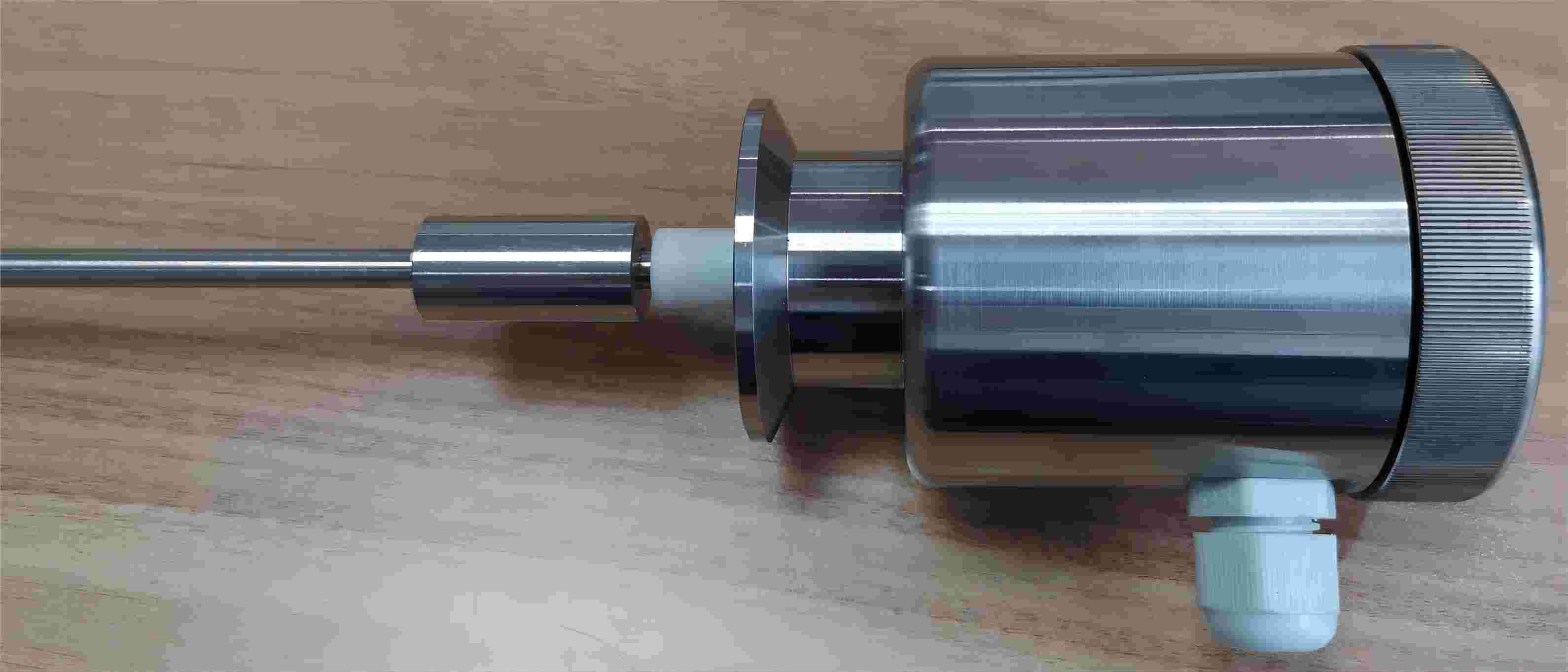

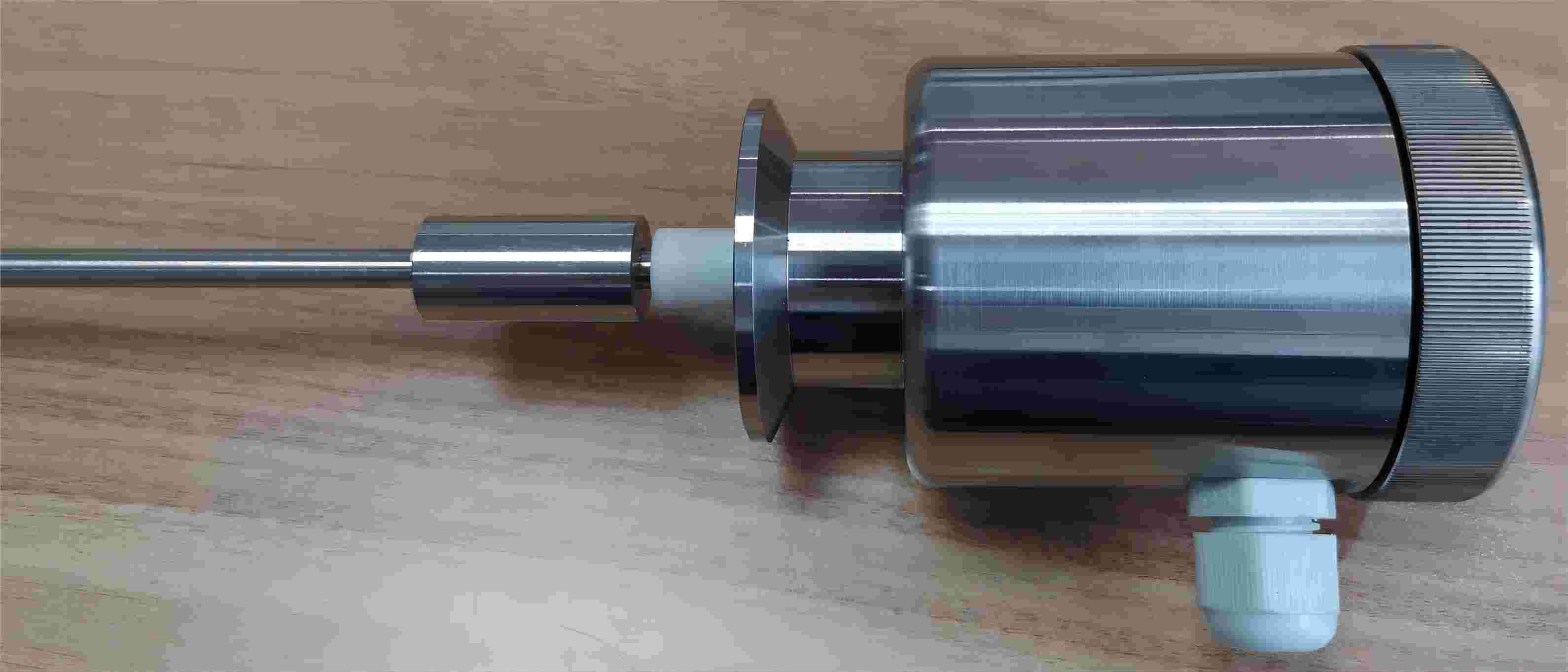

Automated vacuum defoaming in the gelatin melting of soft capsules first requires sensing the liquid level of the gel foam. Due to the common unreliability and susceptibility to damage of externally purchased liquid level sensors, Beijing Summit Pharmatech Co., Ltd. has designed and manufactured a specialized foam liquid level sensor for the automation of gelation in soft capsules. This foam liquid level sensor is suitable for animal and plant-based gel melting, resistant to high temperatures, withstand positive pressure, and vacuum negative pressure. It features a quick-install structure, making it easy to retrofit into customers' existing gelatin melting tanks for the automatic vacuum defoaming of softgel capsules.

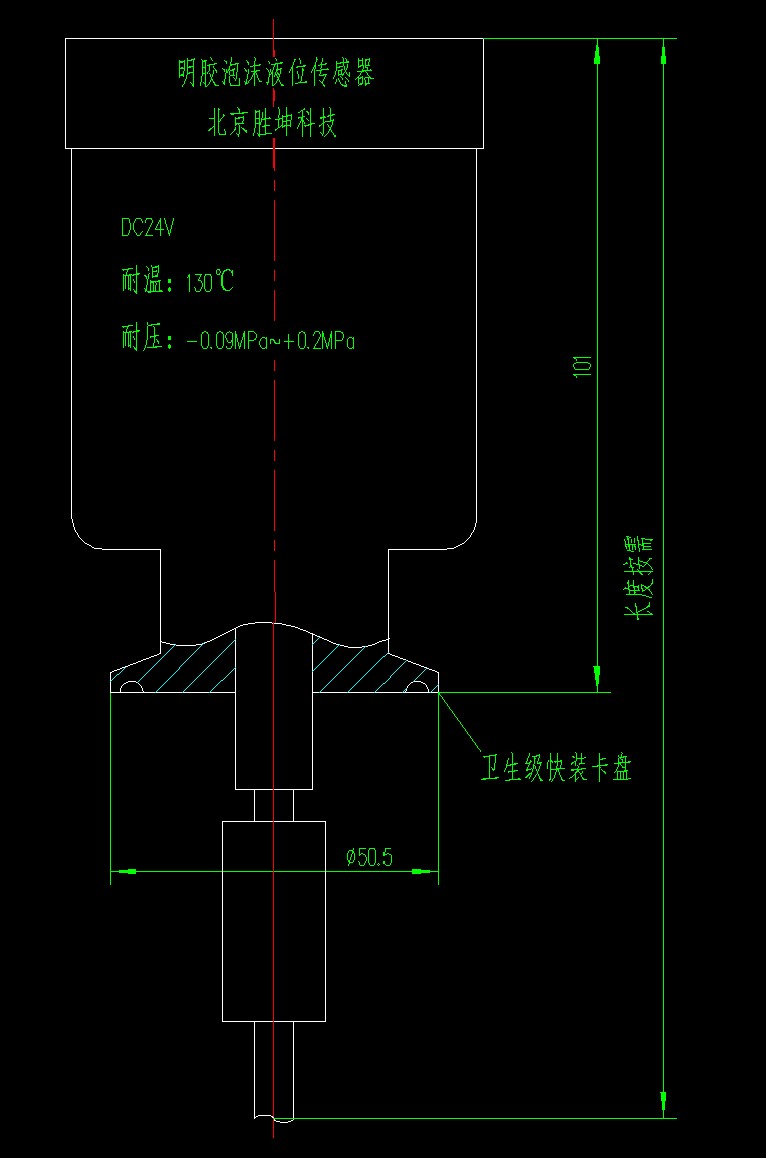

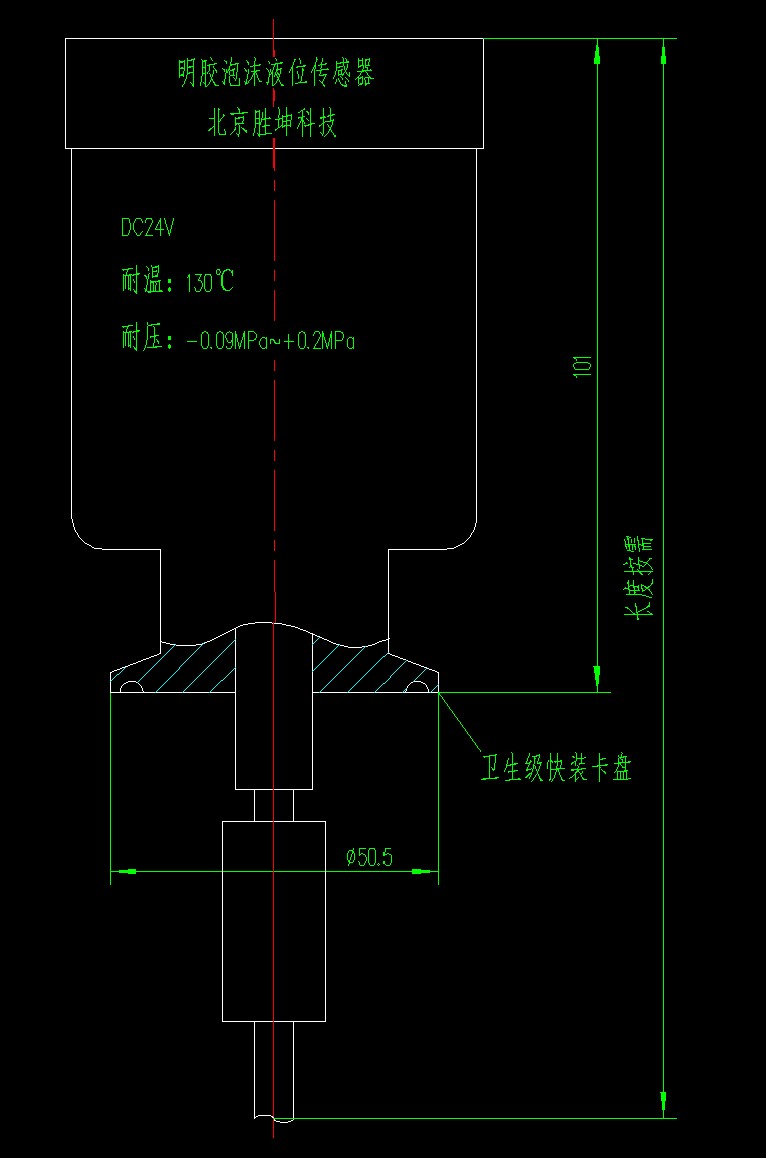

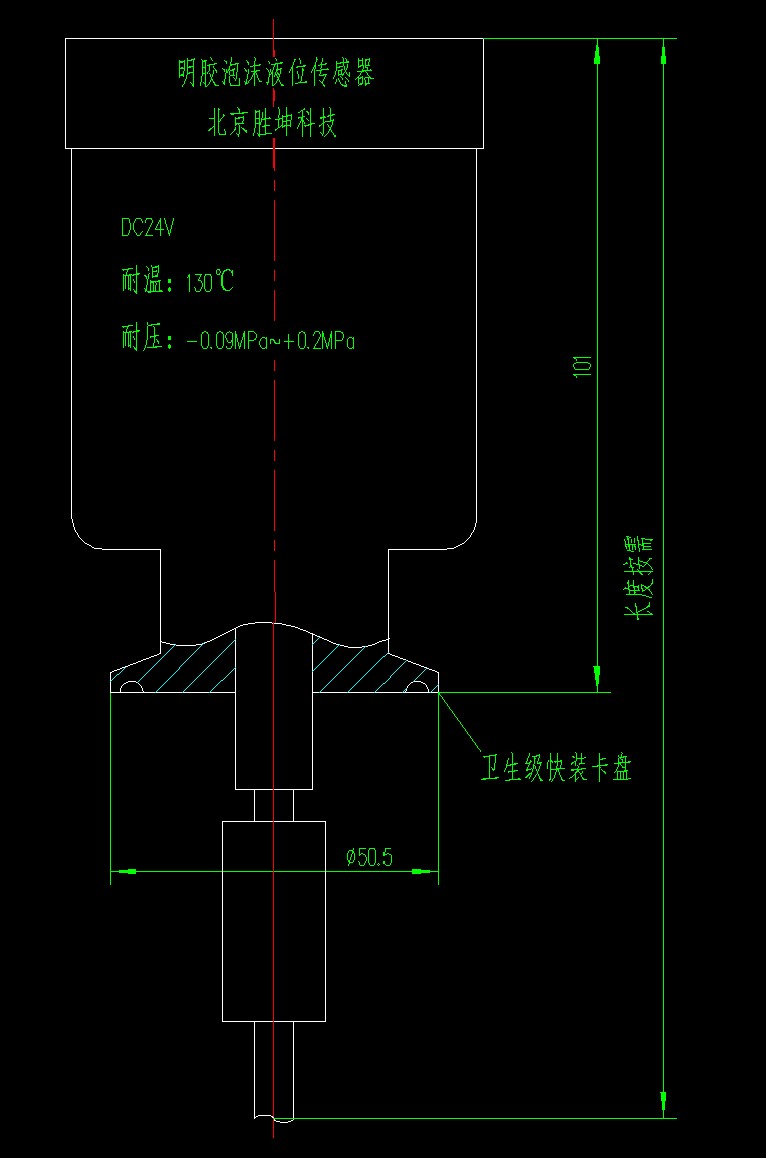

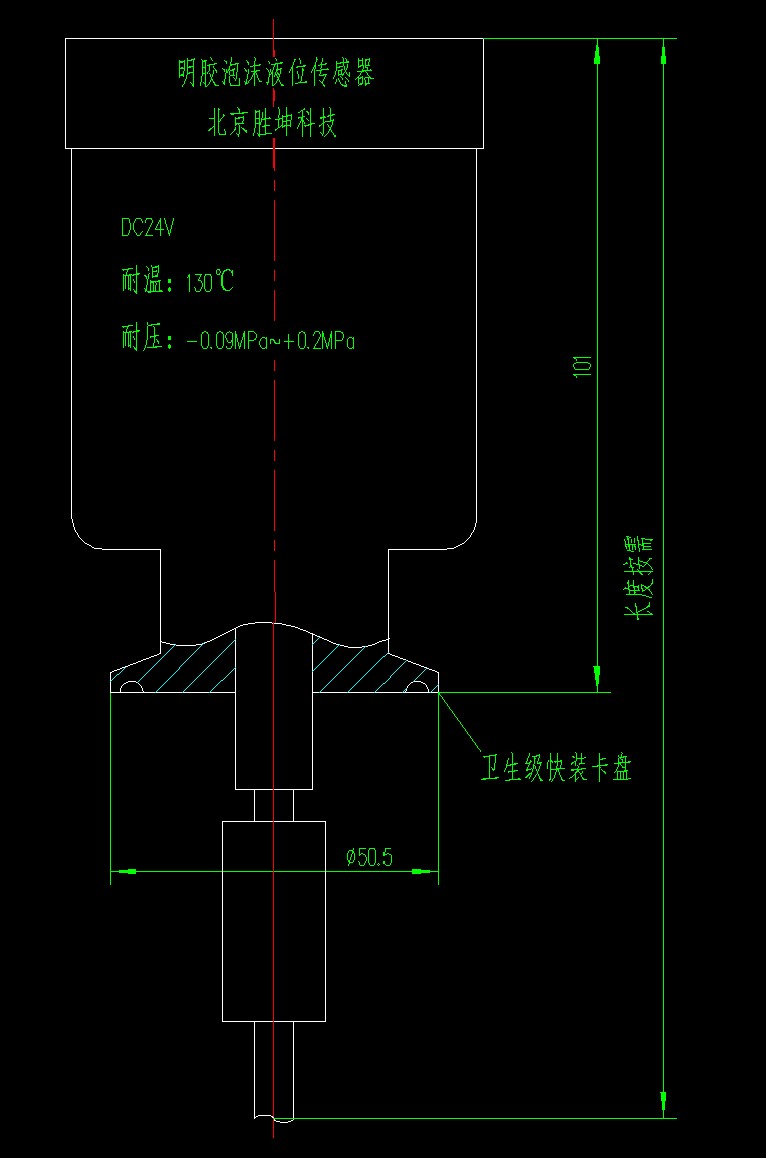

The dimensions of softgel gelatin foam level sensor:

During the production process of soft capsules, the gelation process is essential and crucial, with vacuum defoaming being a key step in the gelatin melting of softgel capsules.

Conventional vacuum defoaming in the gelatin melting of soft capsules requires manual control of the air inlet valve, vacuum valve, and vacuum pump of the gelatin meltign tank by the operator, which is time-consuming and laborious. Due to variations in operators' techniques, different results can be obtained when different gelatin melting workers perform vacuum defoaming, leading to variations in the water content of gel batches. Automating the vacuum defoaming process in the gelatin melting of soft capsules can effectively address this issue.

Automated vacuum defoaming in the gelatin melting of soft capsules first requires sensing the liquid level of the gel foam. Due to the common unreliability and susceptibility to damage of externally purchased liquid level sensors, Beijing Summit Pharmatech Co., Ltd. has designed and manufactured a specialized foam liquid level sensor for the automation of gelation in soft capsules. This foam liquid level sensor is suitable for animal and plant-based gel melting, resistant to high temperatures, withstand positive pressure, and vacuum negative pressure. It features a quick-install structure, making it easy to retrofit into customers' existing gelatin melting tanks for the automatic vacuum defoaming of softgel capsules.

The dimensions of softgel gelatin foam level sensor:

During the production process of soft capsules, the gelation process is essential and crucial, with vacuum defoaming being a key step in the gelatin melting of softgel capsules.

Conventional vacuum defoaming in the gelatin melting of soft capsules requires manual control of the air inlet valve, vacuum valve, and vacuum pump of the gelatin meltign tank by the operator, which is time-consuming and laborious. Due to variations in operators' techniques, different results can be obtained when different gelatin melting workers perform vacuum defoaming, leading to variations in the water content of gel batches. Automating the vacuum defoaming process in the gelatin melting of soft capsules can effectively address this issue.

Automated vacuum defoaming in the gelatin melting of soft capsules first requires sensing the liquid level of the gel foam. Due to the common unreliability and susceptibility to damage of externally purchased liquid level sensors, Beijing Summit Pharmatech Co., Ltd. has designed and manufactured a specialized foam liquid level sensor for the automation of gelation in soft capsules. This foam liquid level sensor is suitable for animal and plant-based gel melting, resistant to high temperatures, withstand positive pressure, and vacuum negative pressure. It features a quick-install structure, making it easy to retrofit into customers' existing gelatin melting tanks for the automatic vacuum defoaming of softgel capsules.

The dimensions of softgel gelatin foam level sensor:

During the production process of soft capsules, the gelation process is essential and crucial, with vacuum defoaming being a key step in the gelatin melting of softgel capsules.

Conventional vacuum defoaming in the gelatin melting of soft capsules requires manual control of the air inlet valve, vacuum valve, and vacuum pump of the gelatin meltign tank by the operator, which is time-consuming and laborious. Due to variations in operators' techniques, different results can be obtained when different gelatin melting workers perform vacuum defoaming, leading to variations in the water content of gel batches. Automating the vacuum defoaming process in the gelatin melting of soft capsules can effectively address this issue.

Automated vacuum defoaming in the gelatin melting of soft capsules first requires sensing the liquid level of the gel foam. Due to the common unreliability and susceptibility to damage of externally purchased liquid level sensors, Beijing Summit Pharmatech Co., Ltd. has designed and manufactured a specialized foam liquid level sensor for the automation of gelation in soft capsules. This foam liquid level sensor is suitable for animal and plant-based gel melting, resistant to high temperatures, withstand positive pressure, and vacuum negative pressure. It features a quick-install structure, making it easy to retrofit into customers' existing gelatin melting tanks for the automatic vacuum defoaming of softgel capsules.

The dimensions of softgel gelatin foam level sensor: